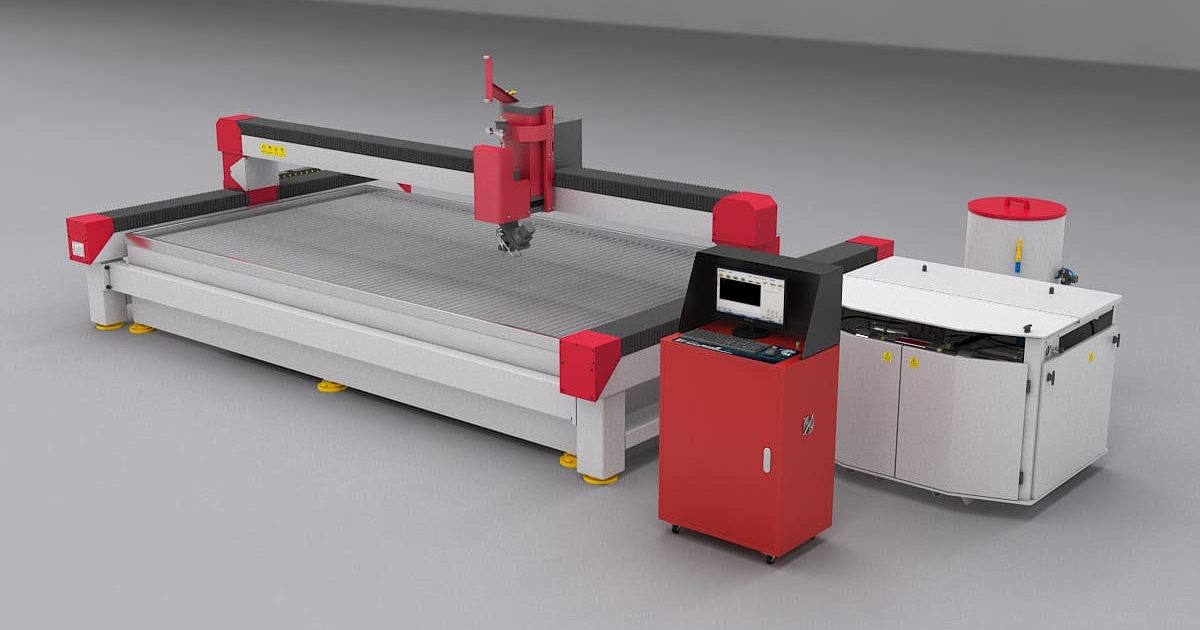

In today's advanced manufacturing industry, CNC (Computer Numerical Control) machines play a crucial role in metal fabrication. In this comprehensive guide, we will explore the key factors to consider when selecting a CNC machine for your metal fabrication needs.

1. Understanding Your Metal Fabrication Requirements

The first step in choosing the right CNC machine for metal fabrication is to understand your specific requirements. Consider the type of metal you work with, the thickness and size of the parts you need to produce, and the complexity of the designs. Pop over to this site if you want to choose the best CNC machine for metal fabrication.

2. Machine Size and Capacity

The size and capacity of the CNC machine are crucial factors to consider. Determine the maximum size and weight of the parts you will be working with and ensure that the machine can handle those dimensions.

3. Precision and Accuracy

Precision and accuracy are critical in metal fabrication, as even the slightest deviation can result in faulty parts. When choosing a CNC machine, pay close attention to its precision and accuracy specifications.

4. Machine Speed and Productivity

The speed and productivity of the CNC machine are important considerations for any metal fabrication business. Faster machines can increase production output and reduce manufacturing lead times.

5. Machine Durability and Reliability

Investing in a CNC machine for metal fabrication is a significant financial commitment. Therefore, it is crucial to choose a machine that is durable and reliable. Consider the machine's construction, build quality, and the materials used.

Conclusion

Choosing the best CNC machine for metal fabrication requires careful consideration of various factors, including your specific requirements, machine size and capacity, precision and accuracy, speed and productivity, durability and reliability, flexibility and versatility, and cost considerations.